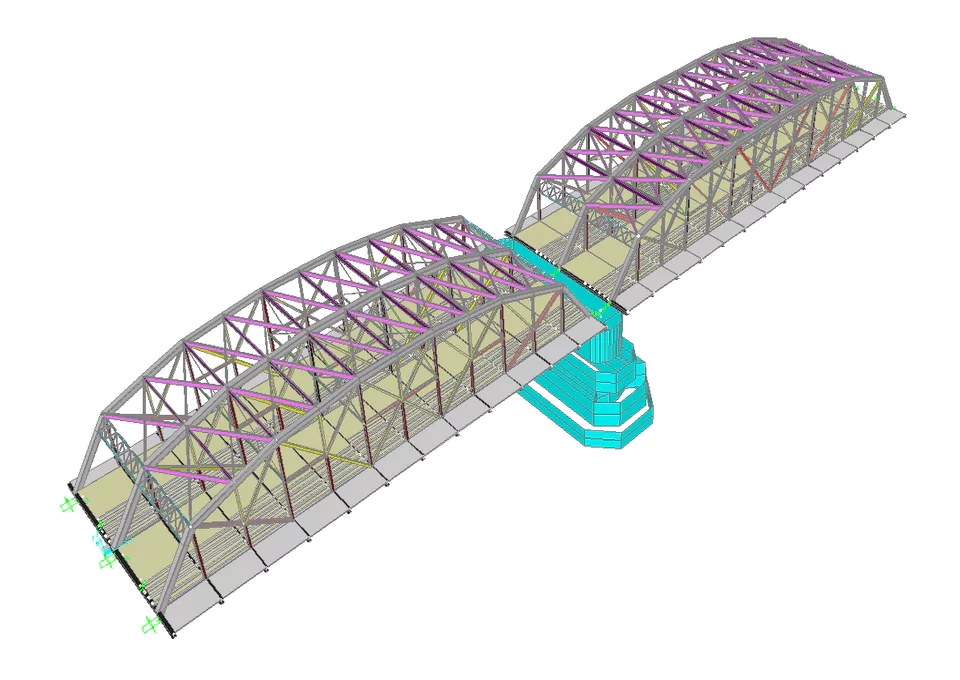

Upgrading a Historic Steel Bridge

Spanning the Pasig River, the two-span truss bridge plays a vital role in Manila’s transportation network, carrying one of the city’s major roadways while accommodating petrochemical tankers and other vessels. Built in the 1950s, the Ayala Bridge had suffered extensive steel corrosion and bearing deterioration, leaving it structurally compromised and unable to meet modern highway and seismic protection standards—making it highly vulnerable to earthquakes. Additionally, limited clearance beneath the bridge restricted vessel passage to low tide. To resolve this, the bridge was raised 27.5 inches using strand jacks, marking a groundbreaking engineering achievement in the Philippines.