Bridges are subjected to a wide range of forces from numerous sources, including the structure’s own weight, material shrinkage and creep, wind pressure, thermal expansion, traffic loads, and horizontal forces caused by acceleration, braking, or skidding. Additional impacts come from collisions, support settlement, and seismic activity.

Freyssinet’s large assortment of bearing systems are engineered to safely handle these complex loads while allowing for controlled movement and rotation of the superstructure.

-

ApplicationsBridges

Buildings

Stadiums

Water infrastructure

Energy infrastructure

Freyssinet TETRON® Bearings

Freyssinet offers a comprehensive range of TETRON® structural bearings, developed around five core designs to meet the specific needs of complex engineering projects:

- Elastomeric bearings

- Pot bearings

- Spherical bearings

- Guide and restraint bearings

- Linear rocker bearings

Each bearing type is available in three operating configurations, allowing for various combinations of translational and rotational movement:

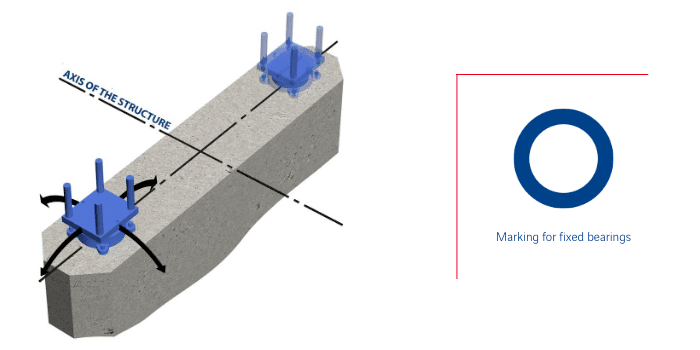

- Fixed Bearings

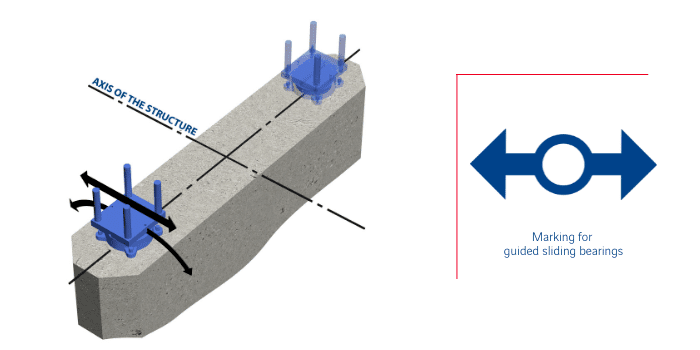

- Guided-Sliding Bearings

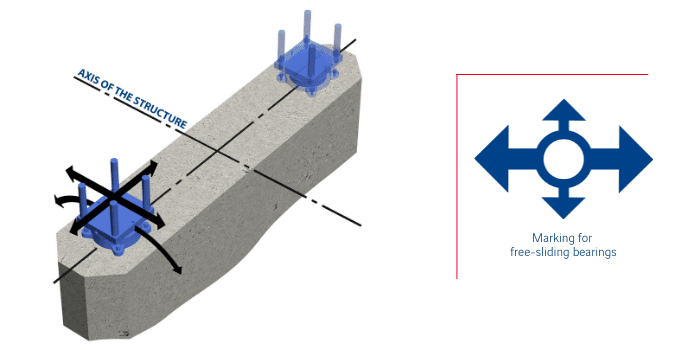

- Free-Sliding Bearings

Quality Assurance & Standards Compliance

All Freyssinet bearings are CE Marked and custom-manufactured to meet the unique requirements of each structure. We design to the most widely accepted international standards, including:

- EN 1337 (Europe)

- BS 5400 (United Kingdom)

- AASHTO LRFD 2012 (United States)

- AS 5100 (Australia)

- Transfer of vertical loads

- Transfer of horizontal forces both in longitudinal and transversal direction

- Sliding movements restrained

- Rotations enabled

- Transfer of vertical loads

- Sliding movements in one horizontal direction

- Transfer of horizontal forces in the other horizontal direction

- Rotations enabled

- Transfer of vertical loads

- Movements in both horizontal directions

- No transfer of external horizontal forces

- Rotations enabled

Freyssinet offers a tailored bearings range designed to meet the complex demands of modern infrastructure. Beyond standard solutions, we develop and test a variety of bespoke bearing systems engineered to project-specific requirements. This specialized bearings range includes:

- Uplift Bearings – Including double-cap spherical configurations designed to withstand uplift loads in service

- Launch-Over Bearings – Permanent solutions optimized for bridge construction via the incremental launching method

- Sliding Pads – Designed for sliding, skidding, or launching operations, featuring enhanced materials for superior movement control

- Jackable Bearings – Allow vertical load adjustment during both construction and in-service phases (single and multiple jacking options)

- Seismic-Integrated Bearings – Fitted with viscous dampers or shock transmission units to deliver resilience in seismic conditions

- Moment-Restraining Bearings – Cylindrical and other configurations engineered to restrict unwanted rotational movement

- Horizontal-Stiffness Bearings – Manufactured to provide the required resistance to horizontal forces

- Acoustic Isolation Bearings – Ideal for noise-sensitive environments, reducing vibrational impact from structural loads

Each custom component in our bearings range is a product of close collaboration between Freyssinet’s structural engineers and bearing specialists—ensuring optimal performance, precision, and long-term reliability.

From Design to Long-Term Maintenance

Assessment & Design Services

Our dedicated technical department, Atlante, based in Italy, provides expert guidance from the earliest stages of your project. Working closely with your team, Atlante helps select the most suitable bearing type and size to meet your structural requirements and budget. With deep expertise in both structural and mechanical engineering, our engineers and draftsmen use advanced design software to produce precise 3D drawings tailored to your project.

In-House Manufacturing & Quality Assurance

Freyssinet’s TETRON® bearings range is manufactured entirely in-house, allowing us to integrate every critical phase—from design and prototype testing to production, quality control, and logistics. Our test center, ISOLAB, located near the Bearing Technical Department in Italy, is recognized as an official laboratory. It is fully equipped to conduct both static and dynamic tests according to international standards, guaranteeing product quality and performance.

Installation Support

We offer technical assistance or complete installation services for your bearings range, provided by our global network of experienced specialists. Freyssinet teams ensure every installation meets design specifications and project timelines with precision and care.

Inspection & Maintenance

Every delivery includes a tailored maintenance guide that outlines inspection intervals based on structural characteristics and environmental factors. This proactive approach helps maximize the service life of each bearing. Our specialists are available for on-site inspections, offering expert evaluation and support to keep your structures operating at peak efficiency.

Structural Bearing Solutions

Freyssinet offers a versatile bearings range engineered to meet diverse structural demands. Each solution is developed for specific load conditions, movement requirements, and installation constraints.

Acting as elastic connections between structural elements, elastomeric bearings are the most commonly used bearings. They allow the transmission of vertical forces, horizontal movements, structure rotation in any direction and horizontal forces within defined limits.

Designed for high vertical stiffness with minimal resistance to rotation, pot bearings feature an elastomeric pad encased in a steel pot. They offer a cost-effective solution for supporting substantial vertical loads and moderate horizontal forces.

These durable bearings incorporate a spherical plate that allows multidirectional rotation with low friction. They support higher vertical loads and greater rotational movement than pot bearings, making them ideal for demanding structural applications.

TETRON SK guide bearings and TETRON PK restraint bearings are used to transfer significant horizontal forces. They are typically paired with free-sliding bearings to achieve full directional control and load distribution.

Ideal for steel structures, linear rocker bearings provide an economical and robust solution. Rotation is permitted in only one direction, and vertical load capacity is determined by the bearing’s dimensions.

To tailor our bearings range to your project’s environmental or design challenges, Freyssinet provides optional features that:

- Minimize installation footprint

- Simplify mounting and handling

- Support long-term structural monitoring

As specialists in bridge infrastructure, Freyssinet provides end-to-end support in inspecting, diagnosing, and replacing damaged bearings. Our maintenance services help preserve safety, restore traffic function, and extend bearing life for highway and transport authorities.

Freyssinet flat jacks are precision-engineered hydraulic devices used for temporary or permanent load transfer applications. They provide accurate control for leveling, lifting, or adjusting structural elements. Flat jacks are especially useful during bearing replacement, bridge realignment, or staged load transfers, and can be equipped with monitoring systems for added operational oversight.

Contact Freyssinet Today!

Thank you for your interest in Freyssinet, Inc. To discuss a specific project, sign up for our newsletter, schedule a presentation, or request other information, please fill out the form below and we will contact you shortly.